Sustainability

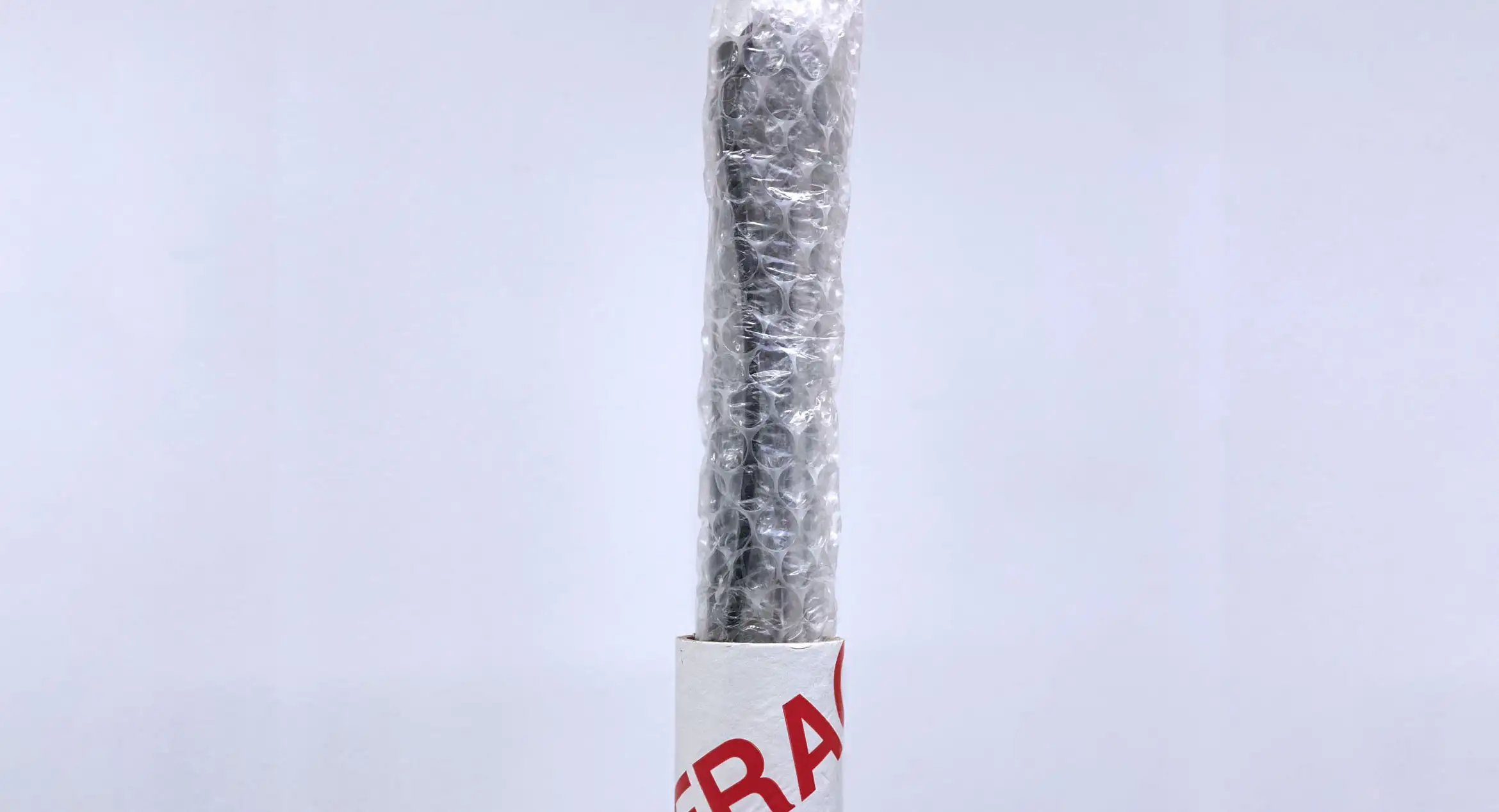

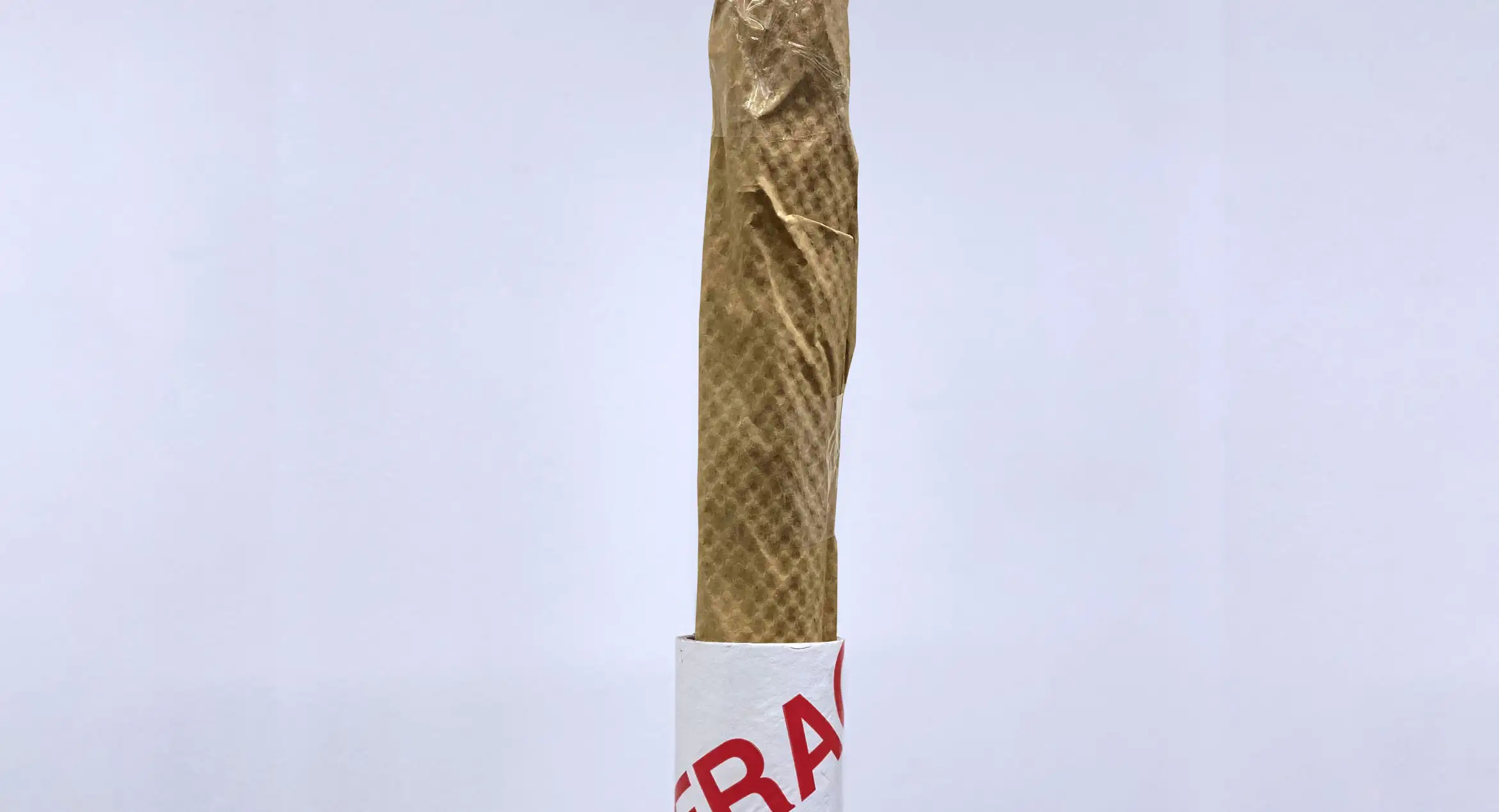

As part of our commitment to environmental well-being and a circular economy here at Portland Lighting, we have actively reduced plastic packaging by 90%. We are also constantly developing and looking at different ways we can reduce our waste and carbon footprint, to minimise our environmental impact and benefit everyone. You already know what we do, but this is what we stand for.

Below are some of the ways we have worked, and continue to work, to achieve this: